This course is about the stages of the clothing industry and recognizing the different types of machines and their basic elements. Students learn to understand the differences between industrial machines used for the same purpose. They can estimate the differences between machine types and the main elements of machines used in each stage. Students learn to use communication technology tools, research, and self-learning.

Professional Information

1. Overall aims of the course

Understanding the stages of the clothing industry.

Recognize the necessary machines used in every step of the clothing industry, including every machine's essential elements.

Applying some practice using available industrial machines such as; (straight knives, round knives, industrial sewing machines, notchers etc.).

2. Intended learning outcomes of the course (ILOs)

a. Knowledge and understanding:

a1. Understanding the stages of the garment industry.

a2. Understanding the several types of machines used in the clothing industry.

a3. Analyzing the essential elements of clothing industrial mechanics.

a4. Understanding the differences between industrial machines used for the same purpose.

b. Intellectual skills

b1. Estimate the differences between different machine types.

b2. Recognize the main elements of machines used in each stage.

b3. Choose a suitable machine for each stage of the clothing industry.

c. Professional and practical skills

c1. Efficiently defines each type of machine.

c2. Effectively understand the main elements of each machine.

c3. Defines the function of each machine.

d. General and transferable skills

d1. Use communication technology tools.

d2. Self-learning.

d3. Team working.

Professional Information

1. Overall aims of the course

Understanding the stages of the clothing industry.

Recognize the necessary machines used in every step of the clothing industry, including every machine's essential elements.

Applying some practice using available industrial machines such as; (straight knives, round knives, industrial sewing machines, notchers etc.).

2. Intended learning outcomes of the course (ILOs)

a. Knowledge and understanding:

a1. Understanding the stages of the garment industry.

a2. Understanding the several types of machines used in the clothing industry.

a3. Analyzing the essential elements of clothing industrial mechanics.

a4. Understanding the differences between industrial machines used for the same purpose.

b. Intellectual skills

b1. Estimate the differences between different machine types.

b2. Recognize the main elements of machines used in each stage.

b3. Choose a suitable machine for each stage of the clothing industry.

c. Professional and practical skills

c1. Efficiently defines each type of machine.

c2. Effectively understand the main elements of each machine.

c3. Defines the function of each machine.

d. General and transferable skills

d1. Use communication technology tools.

d2. Self-learning.

d3. Team working.

- Teacher: هبة زكريا محمد أبو حشيش .

- Teacher: سناء صلاح الدين شكرى .

- Teacher: ألاء أشرف السيد محمد .

- Teacher: نجلاء عبد العظيم أمين السيد .

- Teacher: أمنية خيرى أحمد محمد .

- Teacher: وفاء انور السيد على .

B- Professional Information

1 – Overall aims of course

The course aims to develop artistic ability in knitting technology through application and experimental examination. Technology knowledge development about knitting machines using to producing different knitting fabrics.

By the end of this course, students will be.

Understanding the basic terms of knitting technology

Knowledge about different types of knitting machines

Knowledge about different types of knitting constructions

Knowledge about different types of stitches and applying them on machines.

Understanding the relationship between the techniques of knitting and fabric construction produced.

describe the classification, structure, properties and construction of various knitted products

Give information about knit definition, types of knitting machines and how can classify, as well as the basic knitted fabrics constructions.

Differentiation between the difference between knitting and woven.

Understanding the mechanism action of needles on the knitting machines

Able to produce different pieces on knitting machine using applied different structures.

Carry out and run experimental design work in knitting technology.

Technical knowledge about knit loop formation and how to represent or notation of a knit pattern.

-----------------------------

2 – Intended learning outcomes of course (ILOs)

a- Knowledge and understanding:

A1- understanding the knitting terminologies.

A2- understanding different construction of knitting fabrics.

A3- Learning about knit stitches.

A4- To know the loop formation on knit machine.

A5- To know different between warp and weft knitting.

A6- define the different parts of knitting machines.

A7- Understanding the four basics stitches of knitting.

A8- Knowledge of different types of knitting machines

A9- define knit construction and classifying it.

A10- Distinguish between knitting and woven fabric.

A11- mention different types of knitting machines and how to classify it.

A12- identify knit loop and its parts.

A13- recognize the knitting action mechanism of loop formation.

A14- Identify basic types of knit stitches.

A15- distinguish different of represent knitting notation.

A16- identify the basics elements of knitting machines.

A17- Learning about knit, tuck, float and purl stitches.

A18- mention the weft knitting constructions.

b- Intellectual skills

B1- Estimate the differences between different knitted fabric.

B2- Discuss, deduce and interpret of knitting pattern by represent knitting notation.

B3- compare between different properties of different knitted fabrics.

B4- explain of knitting cycle (action mechanism of loop formation).

B5- compare between warp knit and weft knit.

B6- classify different knitting machines.

B7- differentiating between types of knitting stitches.

B8- compare between knitting and woven structures.

B9- speaking about different types of knitting machines.

B10- apply knitting machines available to create different knitting applications.

B11- speak about basic types of knitting stitches and how to apply it.

B12- use knitting pattern to represent knitting notation.

B13- Talking about the different construction of knitting fabrics and their relationship to their properties.

c- Professional and practical skills

C1- apply knitting machines available to create different knitting applications.

C2- Applying different samples using different pattern of knitting constructions.

C3- comparing between different types of knitting machines.

C4- elicit different fabric constructions of knitting fabrics.

C5- implement a special knitwear piece.

C6-speaking about different types of knitting machines.

C7-Carry out and run experimental design work in knitting technology.

C8-applying knitting pattern to represent knitting notation.

d- General and transferable skills.

D1- suggest new.

D2- search about new trends in knitting technology sector

D2-collect verities information about knitting technology.

1 – Overall aims of course

The course aims to develop artistic ability in knitting technology through application and experimental examination. Technology knowledge development about knitting machines using to producing different knitting fabrics.

By the end of this course, students will be.

Understanding the basic terms of knitting technology

Knowledge about different types of knitting machines

Knowledge about different types of knitting constructions

Knowledge about different types of stitches and applying them on machines.

Understanding the relationship between the techniques of knitting and fabric construction produced.

describe the classification, structure, properties and construction of various knitted products

Give information about knit definition, types of knitting machines and how can classify, as well as the basic knitted fabrics constructions.

Differentiation between the difference between knitting and woven.

Understanding the mechanism action of needles on the knitting machines

Able to produce different pieces on knitting machine using applied different structures.

Carry out and run experimental design work in knitting technology.

Technical knowledge about knit loop formation and how to represent or notation of a knit pattern.

-----------------------------

2 – Intended learning outcomes of course (ILOs)

a- Knowledge and understanding:

A1- understanding the knitting terminologies.

A2- understanding different construction of knitting fabrics.

A3- Learning about knit stitches.

A4- To know the loop formation on knit machine.

A5- To know different between warp and weft knitting.

A6- define the different parts of knitting machines.

A7- Understanding the four basics stitches of knitting.

A8- Knowledge of different types of knitting machines

A9- define knit construction and classifying it.

A10- Distinguish between knitting and woven fabric.

A11- mention different types of knitting machines and how to classify it.

A12- identify knit loop and its parts.

A13- recognize the knitting action mechanism of loop formation.

A14- Identify basic types of knit stitches.

A15- distinguish different of represent knitting notation.

A16- identify the basics elements of knitting machines.

A17- Learning about knit, tuck, float and purl stitches.

A18- mention the weft knitting constructions.

b- Intellectual skills

B1- Estimate the differences between different knitted fabric.

B2- Discuss, deduce and interpret of knitting pattern by represent knitting notation.

B3- compare between different properties of different knitted fabrics.

B4- explain of knitting cycle (action mechanism of loop formation).

B5- compare between warp knit and weft knit.

B6- classify different knitting machines.

B7- differentiating between types of knitting stitches.

B8- compare between knitting and woven structures.

B9- speaking about different types of knitting machines.

B10- apply knitting machines available to create different knitting applications.

B11- speak about basic types of knitting stitches and how to apply it.

B12- use knitting pattern to represent knitting notation.

B13- Talking about the different construction of knitting fabrics and their relationship to their properties.

c- Professional and practical skills

C1- apply knitting machines available to create different knitting applications.

C2- Applying different samples using different pattern of knitting constructions.

C3- comparing between different types of knitting machines.

C4- elicit different fabric constructions of knitting fabrics.

C5- implement a special knitwear piece.

C6-speaking about different types of knitting machines.

C7-Carry out and run experimental design work in knitting technology.

C8-applying knitting pattern to represent knitting notation.

d- General and transferable skills.

D1- suggest new.

D2- search about new trends in knitting technology sector

D2-collect verities information about knitting technology.

- Teacher: إيناس محمد عبد الفتاح .

B- Professional Information

1 – Overall aims of course

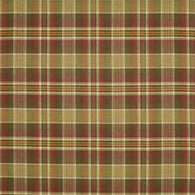

Textile design course aim to learning how to create strips, checks and motives designs suitable for woven fabrics and knowing how to create a color repeat and a textile repeat in the fabric by using traditional methods and CAD programs.

By the end of this course, students will be.

Able to create the weave repeat pattern as well as color repeat.

Knowledge about different types of looms and how to weave a fabric structure

Learning about basics parts of loom and the function of each part.

Understanding about the textile design and weave pattern meaning

Understanding the relationship between the technique of weaving loom and the fabric structures

Understanding the basic elements of woven design.

Knowledge about the basic woven fabric structures such as: plain, twill and satin production of different fabric structures

Understanding the difference between a weave repeat and a color repeat in a fabric.

Able to create different fabric designs strips, checks and motives.

Applying draws and creates strips designs, checked designs and motifs by using traditional methods or CAD design programs

Able to create textile designs by free hand or on designs programs application as Photoshop program.

2 – Intended learning outcomes of course (ILOs)

Knowledge and understanding:

A1- To understand the basic parts of the loom.

A2- To understand the techniques of weaving loom to produce different fabric structures A3- To understand the basics of different fabric structures.

A4- To know and understand the advanced fabric structures.

A5- To know different fabrics using manual loom and applying these weaving fabric structures method.

A6- define the repeating weave pattern.

A7- mentions the functions of loom parts A8- Knowledge of textile design.

A9- knowledge about floats and interlacing

A10- meaning of balanced cloth.

A11- Understanding the weaving process.

A12- understanding the basic elements of textile design.

A13- Knowledge about classification of weaving machine

A14- understanding the color repeat in weave design.

b- Intellectual skills

B1- Estimate the differences between different fabric structure.

B2- Discuss and comment on different techniques to produce weaving fabric structures B3- compare between different fabric structures.

B4- explaining draft plan, lifting plan and denting plan.

B5- applying of stripe, check pattern and motifs by using free sketch papers.

B6- applying Computer aided design for textile design applications.

B7- applying different textile designs suitable for different functions.

B8- comparing between single phase and multi-phase of weaving machine.

B9- Applying different motives designs appropriate to different purposes.

B10- Applying different checks designs appropriate to different purposes.

c- Professional and practical skills

C1- creating new designs suitable to applying women, men and kids' garments.

C2- speaking about different types of looms.

C3- comparing between basic and advanced looms C4- Effectively understand the main parts of the loom.

C5- comparing between different types of shedding motion tappet, dobby and jacquard.

C6- Using a computer design program (Photoshop program) for creating different designs of strips, checks and motives.

C7- Effectively understand the differences between the techniques used in the production of different fabric structures.

C8- comparing between dobby and jacquard loom.

C9- speaking about different basics of woven structures and the properties of each one.

C10- Differentiation between floats and interlacing in drafting design.

d- General and transferable skills.

D1- suggest new strips and checks design.

D2-collect verities information about textile design.

1 – Overall aims of course

Textile design course aim to learning how to create strips, checks and motives designs suitable for woven fabrics and knowing how to create a color repeat and a textile repeat in the fabric by using traditional methods and CAD programs.

By the end of this course, students will be.

Able to create the weave repeat pattern as well as color repeat.

Knowledge about different types of looms and how to weave a fabric structure

Learning about basics parts of loom and the function of each part.

Understanding about the textile design and weave pattern meaning

Understanding the relationship between the technique of weaving loom and the fabric structures

Understanding the basic elements of woven design.

Knowledge about the basic woven fabric structures such as: plain, twill and satin production of different fabric structures

Understanding the difference between a weave repeat and a color repeat in a fabric.

Able to create different fabric designs strips, checks and motives.

Applying draws and creates strips designs, checked designs and motifs by using traditional methods or CAD design programs

Able to create textile designs by free hand or on designs programs application as Photoshop program.

2 – Intended learning outcomes of course (ILOs)

Knowledge and understanding:

A1- To understand the basic parts of the loom.

A2- To understand the techniques of weaving loom to produce different fabric structures A3- To understand the basics of different fabric structures.

A4- To know and understand the advanced fabric structures.

A5- To know different fabrics using manual loom and applying these weaving fabric structures method.

A6- define the repeating weave pattern.

A7- mentions the functions of loom parts A8- Knowledge of textile design.

A9- knowledge about floats and interlacing

A10- meaning of balanced cloth.

A11- Understanding the weaving process.

A12- understanding the basic elements of textile design.

A13- Knowledge about classification of weaving machine

A14- understanding the color repeat in weave design.

b- Intellectual skills

B1- Estimate the differences between different fabric structure.

B2- Discuss and comment on different techniques to produce weaving fabric structures B3- compare between different fabric structures.

B4- explaining draft plan, lifting plan and denting plan.

B5- applying of stripe, check pattern and motifs by using free sketch papers.

B6- applying Computer aided design for textile design applications.

B7- applying different textile designs suitable for different functions.

B8- comparing between single phase and multi-phase of weaving machine.

B9- Applying different motives designs appropriate to different purposes.

B10- Applying different checks designs appropriate to different purposes.

c- Professional and practical skills

C1- creating new designs suitable to applying women, men and kids' garments.

C2- speaking about different types of looms.

C3- comparing between basic and advanced looms C4- Effectively understand the main parts of the loom.

C5- comparing between different types of shedding motion tappet, dobby and jacquard.

C6- Using a computer design program (Photoshop program) for creating different designs of strips, checks and motives.

C7- Effectively understand the differences between the techniques used in the production of different fabric structures.

C8- comparing between dobby and jacquard loom.

C9- speaking about different basics of woven structures and the properties of each one.

C10- Differentiation between floats and interlacing in drafting design.

d- General and transferable skills.

D1- suggest new strips and checks design.

D2-collect verities information about textile design.

- Teacher: إيناس محمد عبد الفتاح .

- Teacher: سناء صلاح الدين شكرى .

1 – Overall aims of course

This course develops and extends the range of skills making drafts and paper patterns, their layout, methods of flat pattern making for men's classic, casual shirts, sportswear, and trousers and their variations. These concepts have to be applied in the creation of fashion ensembles.

Students will learn advanced pattern making with multiple variations of the basic blocks. Students will learn the technique of style reading and developing patterns for shirts and trousers. Students will be further enriched with the experience of making commercial paper patterns and grading patterns.

2 – Intended learning outcomes of course (ILOs)

a- Knowledge and understanding:

a1- Define the terms used when drafting basic men's patterns such as block, Enclosed seams, fitting lines, fly, fork, fly, seat wedge, and etc.

a2- List the measurements required to draft the basic pattern for men's shirts, trousers and sports wear

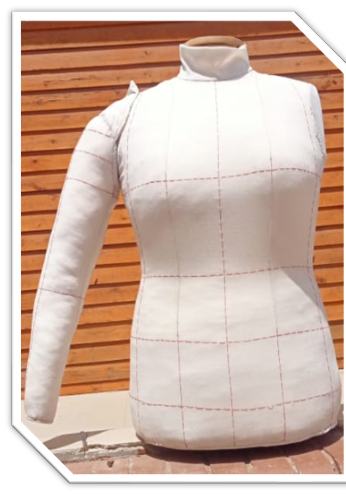

A3- List Basic principles of drafting patterns on paper and testing them in muslin on three-dimensional forms for men's shirts, trousers and sports wear

.

b- Intellectual skills

b1- Differentiate between the flat blocks and the form blocks.

b2- Differentiate between the different types of men's shirts (classic, tailored, casual).

b3- Differentiate between men's figure type.

B-4Define the grain line

B-5Choosing the best fabrics for each style

c- Professional and practical skills

1c- Create the appropriate pattern and pattern alteration for menswear suitable for each design using standard or personal measurements.

2c- Modify the pattern to meet the aimed design.

3c-Estimate the appropriate materials used for shirts, sportswear and trousers.

4c- Select the best finishing technique could be used in each model or Design.

5c- Evaluate the final product from design, material, fit, and finishing techniques.

6c- Design the final personal project with suitable pattern, material, finishing technique, facing, and interfacing.

d- General and transferable skills

d1- Set tasks and manage their time and jobs as well as acquire self and long-life learning.

d2- Use new technological available tools, informant & communication technology.

This course develops and extends the range of skills making drafts and paper patterns, their layout, methods of flat pattern making for men's classic, casual shirts, sportswear, and trousers and their variations. These concepts have to be applied in the creation of fashion ensembles.

Students will learn advanced pattern making with multiple variations of the basic blocks. Students will learn the technique of style reading and developing patterns for shirts and trousers. Students will be further enriched with the experience of making commercial paper patterns and grading patterns.

2 – Intended learning outcomes of course (ILOs)

a- Knowledge and understanding:

a1- Define the terms used when drafting basic men's patterns such as block, Enclosed seams, fitting lines, fly, fork, fly, seat wedge, and etc.

a2- List the measurements required to draft the basic pattern for men's shirts, trousers and sports wear

A3- List Basic principles of drafting patterns on paper and testing them in muslin on three-dimensional forms for men's shirts, trousers and sports wear

.

b- Intellectual skills

b1- Differentiate between the flat blocks and the form blocks.

b2- Differentiate between the different types of men's shirts (classic, tailored, casual).

b3- Differentiate between men's figure type.

B-4Define the grain line

B-5Choosing the best fabrics for each style

c- Professional and practical skills

1c- Create the appropriate pattern and pattern alteration for menswear suitable for each design using standard or personal measurements.

2c- Modify the pattern to meet the aimed design.

3c-Estimate the appropriate materials used for shirts, sportswear and trousers.

4c- Select the best finishing technique could be used in each model or Design.

5c- Evaluate the final product from design, material, fit, and finishing techniques.

6c- Design the final personal project with suitable pattern, material, finishing technique, facing, and interfacing.

d- General and transferable skills

d1- Set tasks and manage their time and jobs as well as acquire self and long-life learning.

d2- Use new technological available tools, informant & communication technology.

- Teacher: كاميليا موسى محمد الزينى .